| No. |

Equipment Type |

Equipment Name |

Equipment Model |

| 1 |

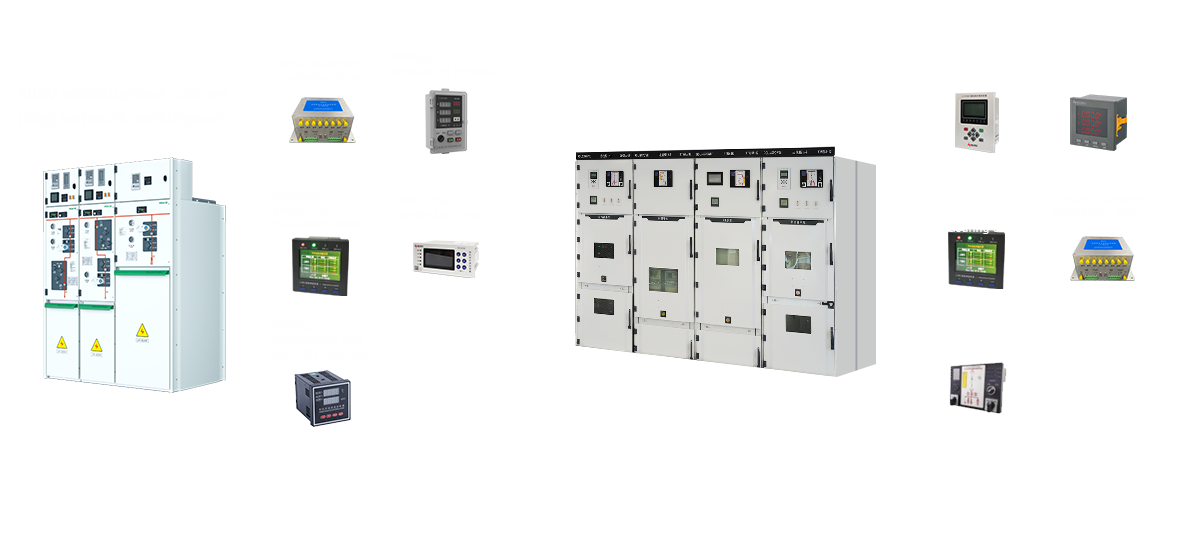

Intelligent high-voltage switchgear (middle placed) |

Integrated Protection Device |

LY-P200 |

| Intelligent Control |

LY-SD20 |

| Partial Discharge Monitoring Device |

LY-MD500 |

| Multifunctional Instrument |

Optional According to Real Requirement |

| Wireless Temperature Measuring Device |

LY401 |

| 2 |

Intelligent high-voltage switchgear (ring network switchgear) |

Wireless Measurement and Control Terminal |

ICS-X100 |

| Integrated Protection Device |

ICS-A100 |

| Partial Discharge Monitoring Device |

LY-MD500 |

| Intelligent Temperature and Humidity Monitoring |

LY-ZWSK |

| Wireless Temperature Measuring Device |

LY401 |

| 3 |

Intelligent Transformer |

Intelligent Transformer Controller |

Optional According to Real Requirement |

| Transformer Noise Sensor |

LY-ZS01 |

| 4 |

Intelligent low-voltage switchgear(frame) |

Intelligent Frame Circuit Breaker |

CKW65 |

| Multifunctional Instrument |

Optional According to Real Requirement |

| Wireless Temperature Measuring Device |

|

| 5 |

Intelligent low-voltage switchgear(plastic case) |

Intelligent plastic case circuit breaker |

CKM68 |

| Guide rail multi-function instrument |

Optional according to Real Requirement |

| 6 |

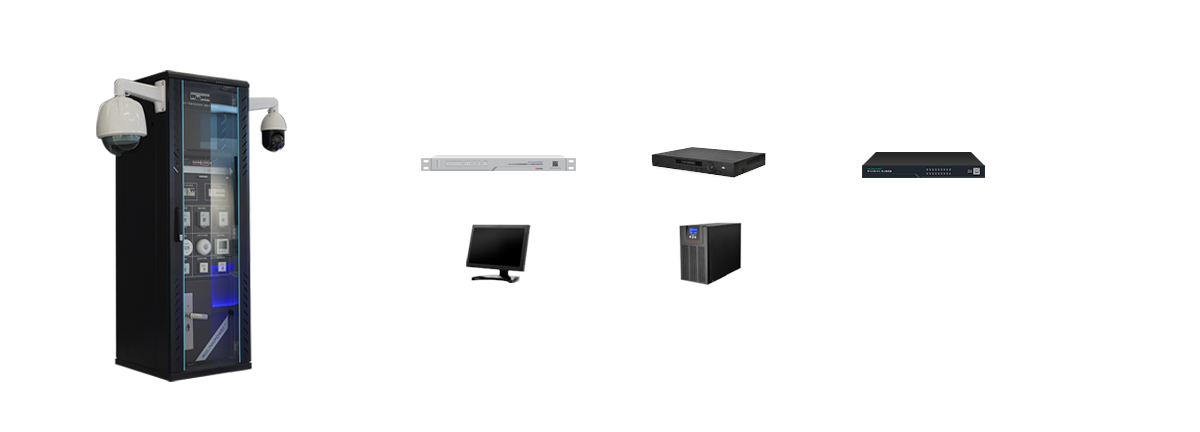

Internet of Things centralized control switchgear in power distribution room |

Standard Monitoring Switchgear |

800*600*2200 (mm) |

| Intelligent Gateway |

CMU-A5000 |

| Hardware Video Recorder |

NVR DS-7708N-K4 |

| Exchanger |

Optional according to Real Requirement |

| Monitor |

Optional according to Real Requirement |

| Power Management System |

Optional according to Real Requirement |

| 7 |

Environmental Monitoring Terminal |

Temperature and Humidity Sensor |

LY-WK01 |

| Water Immersion Sensor |

LY-SJ01 |

| Smoke Sensor |

LY-YW01 |

| SF6 Gas Sensor |

LY-SF601 |

| Ozone Sensor |

LY-CY01 |

| Air Quality Sensor |

LY-KQZL01 |

| Infrared Sensor |

LY-HW01 |

| Wind Machine Linkage Device |

LY-FJ01 |

| Light Linkage Device |

LY-DG01 |

| Pump Linkage Device |

LY-SB01 |

| Air Conditioner Linkage Device |

LY-KT01 |

| 8 |

Video Monitoring Terminal |

Ball Camera |

iDS-2DC4223IWQJ |

| Gun Camera |

DS-2CD2T26EWDQA-L |

| Patrol Robot |

Optional According to Real Requirement |