With the rapid development of urbanization, a large number of high-voltage cables enter the ground, which brings us many problems: the narrow and closed cable trench is easy to produce a large number of toxic and flammable gases, which accelerates the aging of cables. It is easy to explode and cause fire when encountering open fire or cable discharge fault. As the cable trench is underground and interconnected, once a fire occurs, it will spread rapidly and difficult to be extinguished quickly, resulting in huge social and economic losses and even casualties.

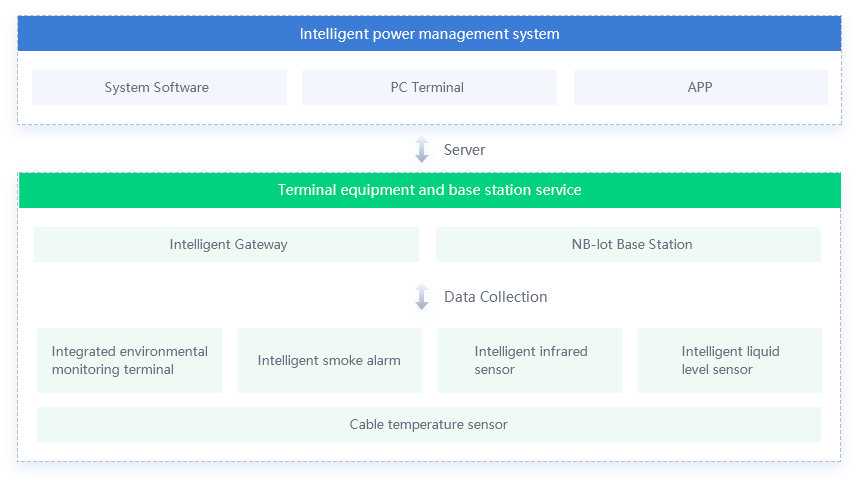

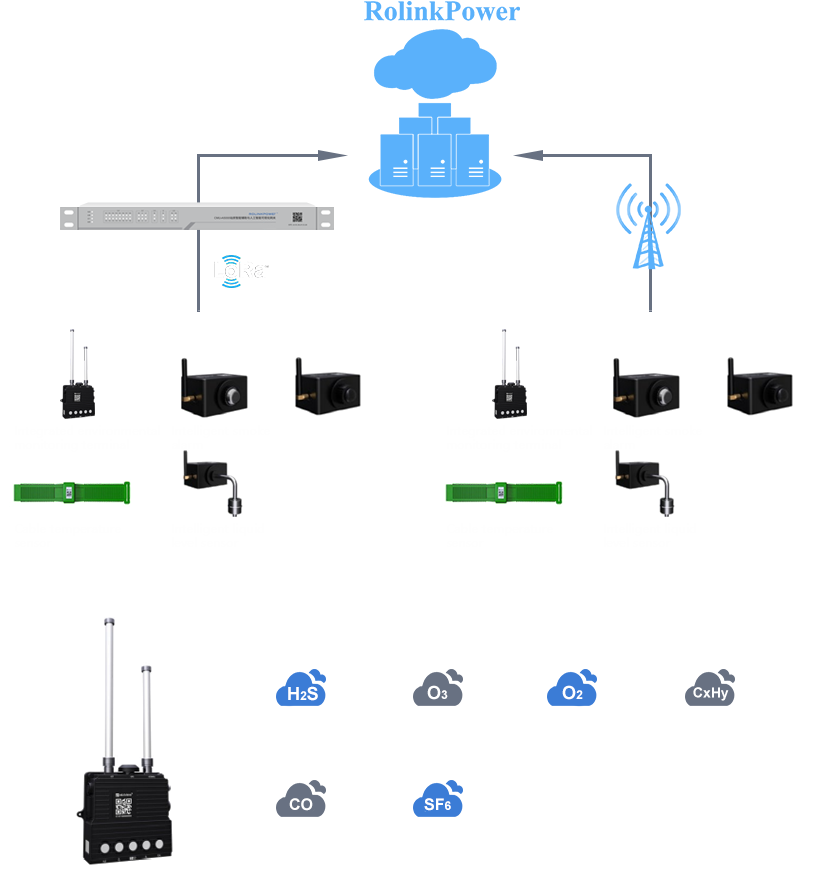

As there is no difference between working power supply and communication signal in cable trench, cable trench monitoring is a blind area in power system management and a difficult point in operation and maintenance. ROLINKPOWER ™’s solution of intelligent power supply system adopts the Internet of Things technology., by installing integrated environmental monitoring terminals and other sensors, online monitoring of the operating parameters, environmental parameters and security status of urban power supply can realize accident warning, change "passive repair" to "active operation and maintenance", and improve the reliability of power supply and consumption. Combined with big data application, it can realize power grid load analysis, cable current carrying capacity expansion assessment, cable duct risk assessment, network topology traceability and other functions. ROLINKPOWER ™ Intelligent power supply system can be widely used in tunnel monitoring, cable trench monitoring, mine monitoring, integrated power station monitoring and other application sites.