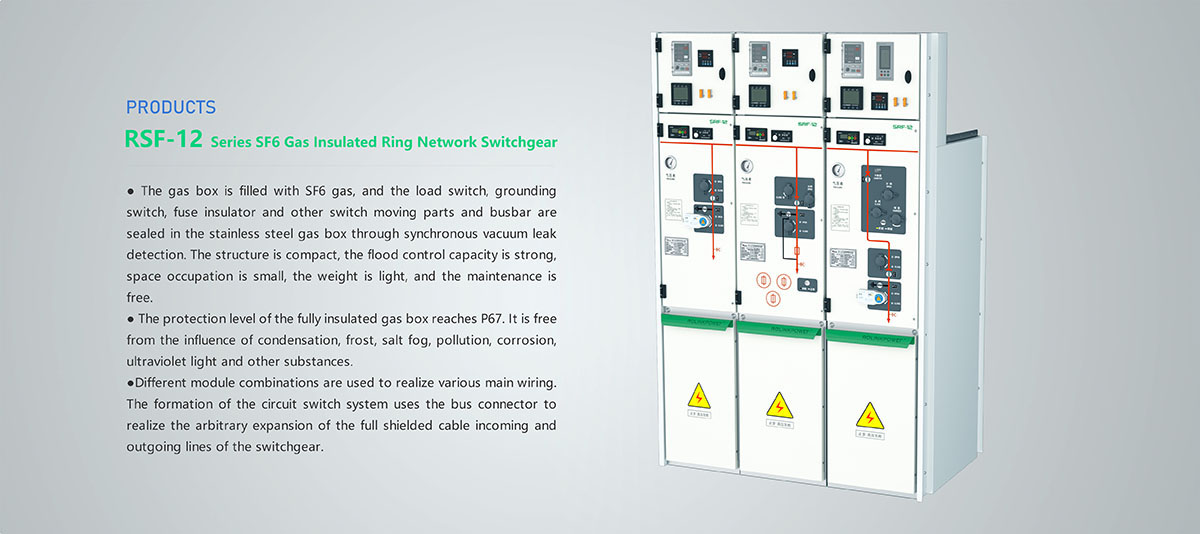

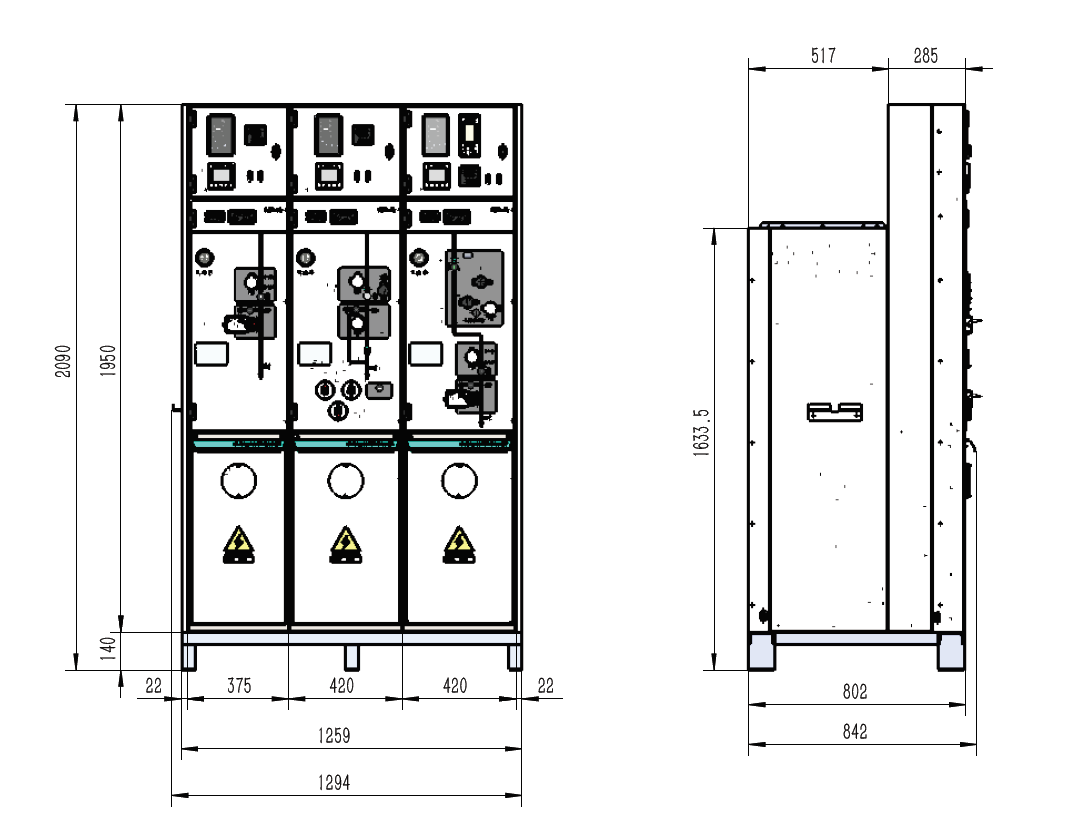

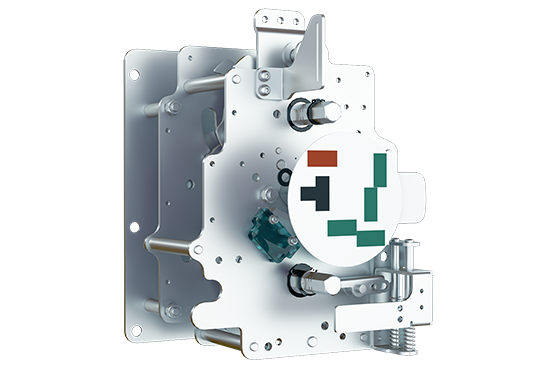

RSF-12 Gas insulated ring network switchgear

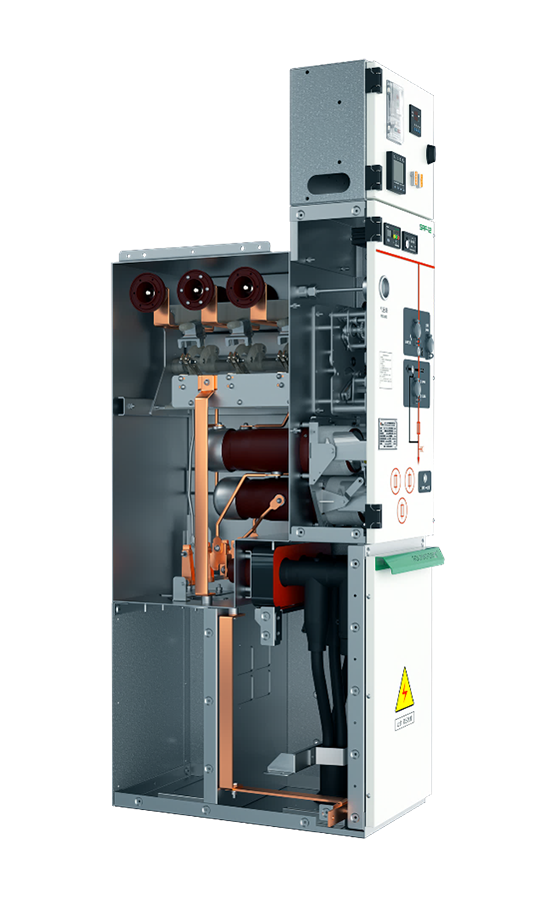

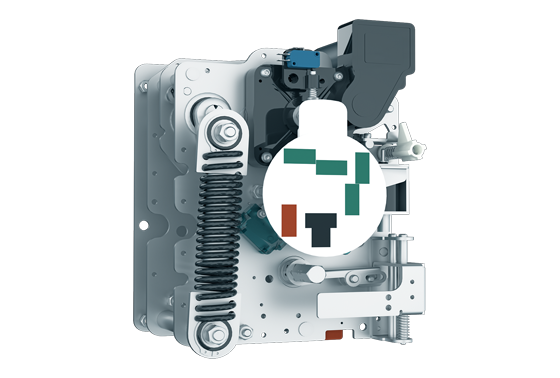

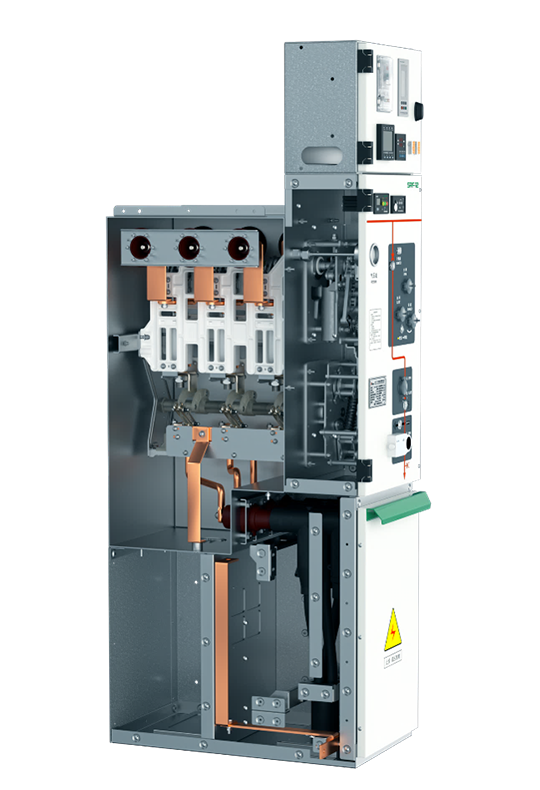

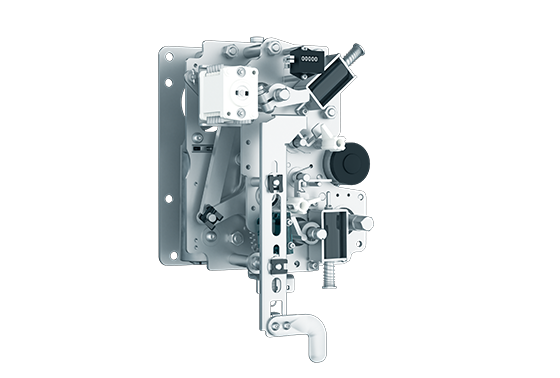

The air box of RSF-12 series aeration switchgear adopts high-quality 3mm thick stainless steel shell. The stainless steel plate is formed by laser cutting and automatically welded by an advanced welding manipulator to ensure the air tightness of the air box. SF6 gas filled in the gas box is vacuumized synchronously for leak detection; The load switch, grounding switch, fuse insulating cylinder and other switch moving parts and bus bars are all sealed in the stainless steel gas box, and the protection grade of the gas filled housing reached IP67.

It shall not be affected by the environment, and shall be resistant to condensation, frost, salt fog, pollution, corrosion, ultraviolet and chemical substances;

All high-voltage live parts and switching elements are sealed in the stainless steel box filled with SF6 gas, with compact structure, small space occupation, light weight and full insulation;

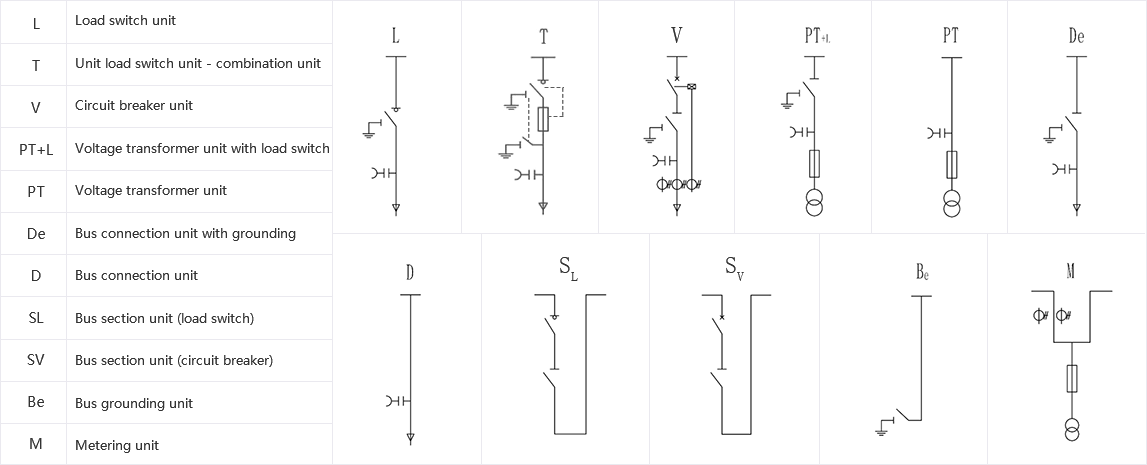

Modular design, with different module combinations to realize various bus bars and form a loop switch system;

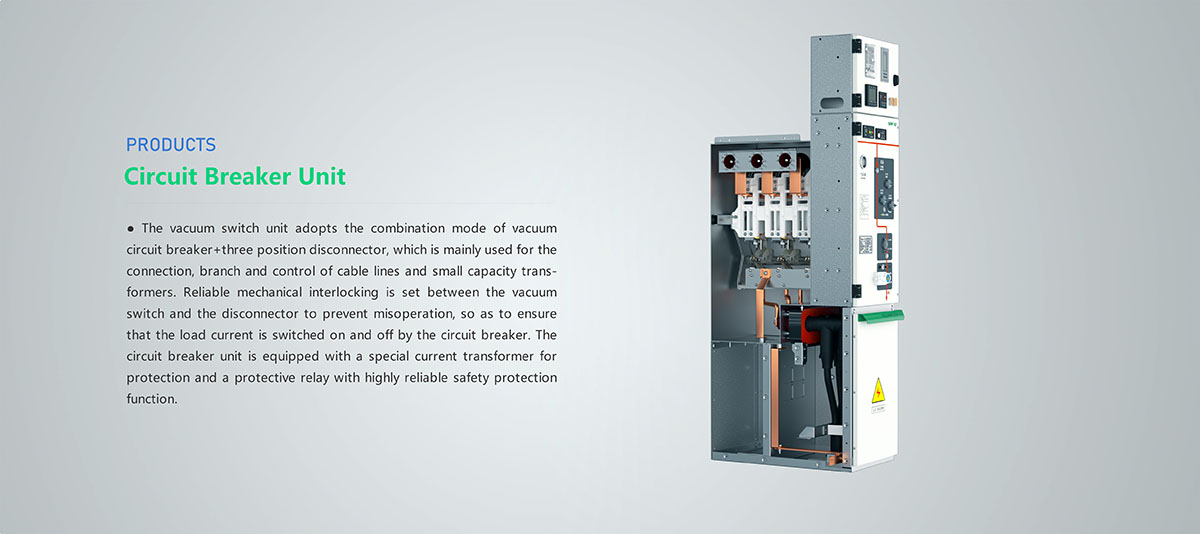

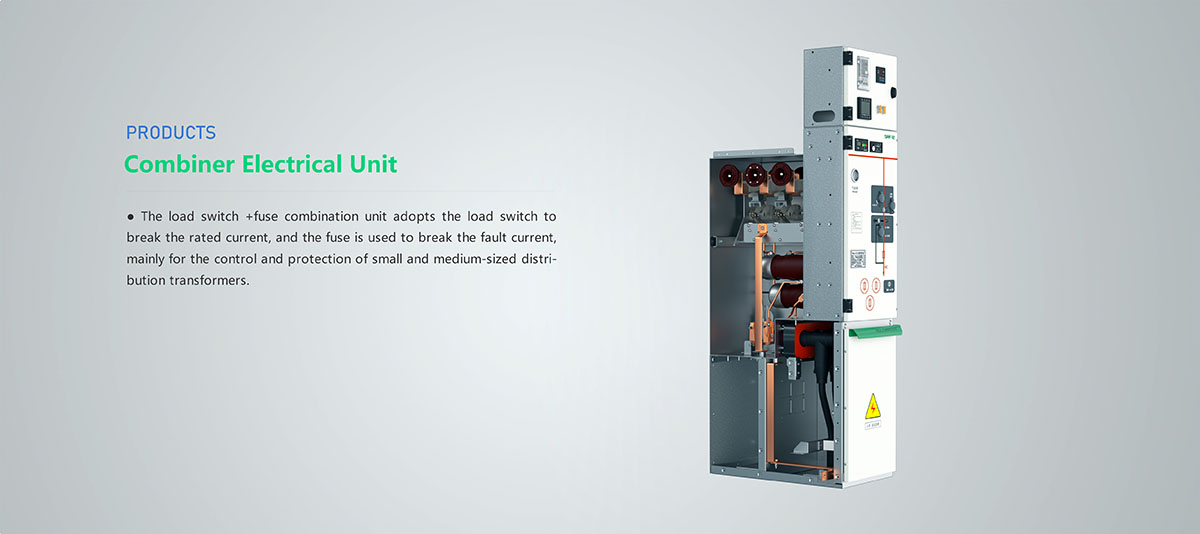

Silicone rubber connector is adopted to realize the plugging of high-voltage components and the arbitrary expansion of the switchgear; Incoming and outgoing lines of fully shielded cables; Vacuum circuit breaker switchgear can be used;

High voltage monitoring element and integrated digital relay can be used; High voltage metering switchgear can be equipped; Remote control and monitoring unit can be added;

Over current relay protection device can be installed; Strong flood control capability, long service life, maintenance free, and low operation cost; Meet the requirements of distribution network automation upgrade.