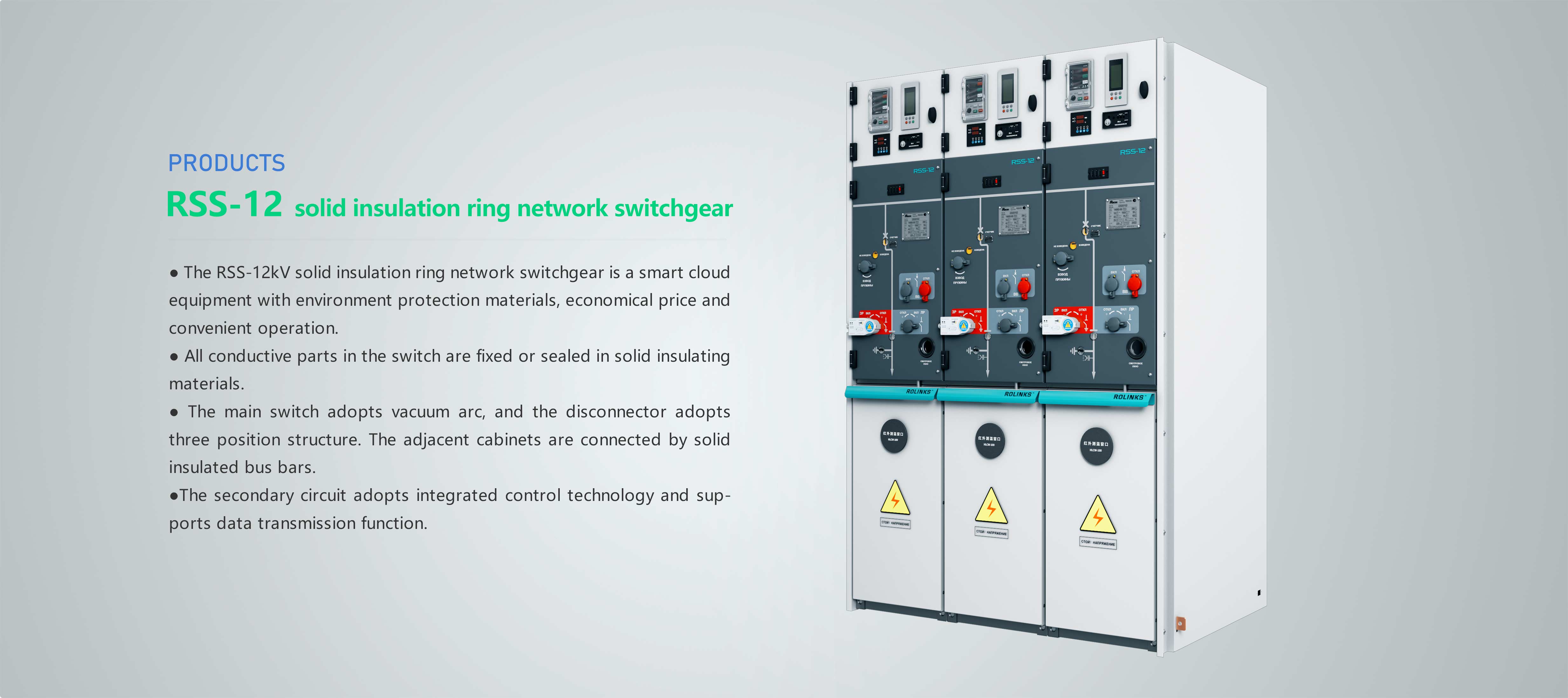

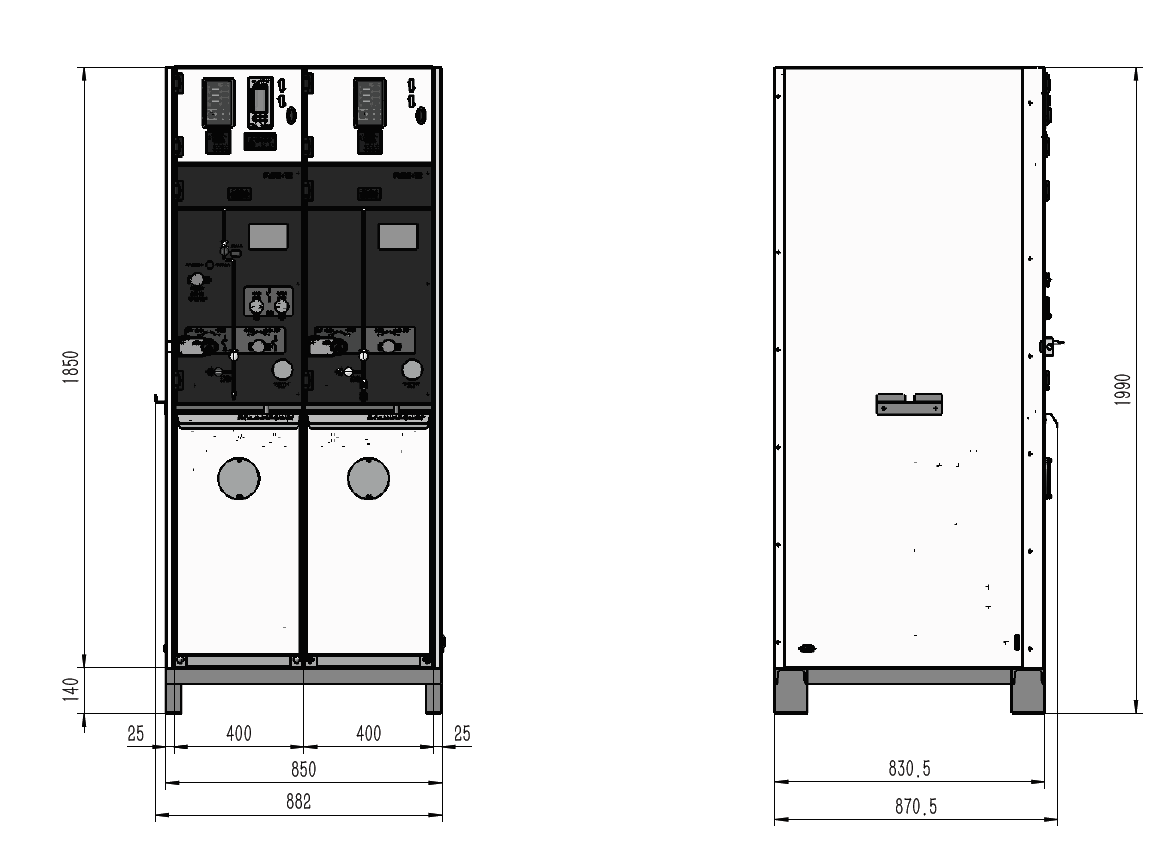

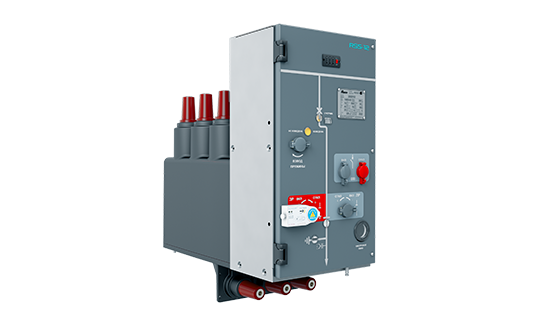

RSS-12 solid insulation ring network switchgear

Since the 1990s, with the continuous acceleration of urbanization and the continuous improvement of power supply reliability, urban overhead lines have gradually moved towards buried cables, and indoor switching stations have gradually been replaced by outdoor switching stations. RSS-12kV switchgear is widely used in urban commercial centers, industrial concentration areas, airports, electrified railways, highways and other power distribution systems with high reliability requirements due to its features of full insulation, touchability, flood control, small size, maintenance free, etc. It can be used independently inside and outside the home, or integrated in prefabricated substations.

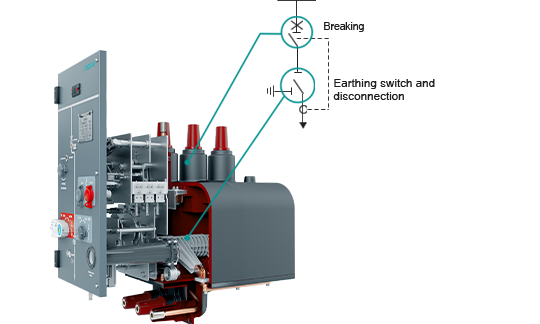

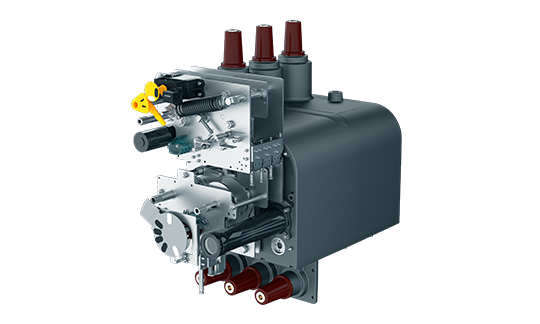

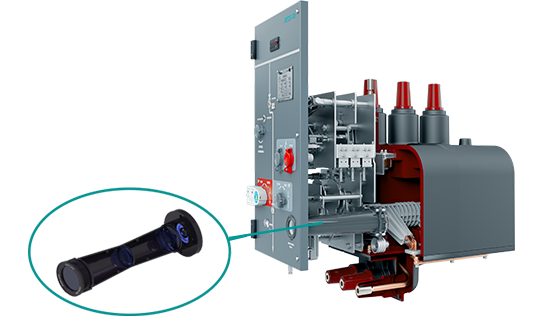

The RSS-12 solid insulation ring network switchgear, high-voltage metal enclosed switchgear is a smart cloud equipment with environment-friendly materials, economical price and convenient operation. All conductive parts in the switch are firmly sealed or sealed in solid insulating materials. The main switch adopts vacuum arc extinguishing, the disconnector adopts three position structure, and adjacent cabinets are connected through solid insulating bus bars. The secondary circuit adopts integrated control technology and supports the data transmission function. When the equipment is installed and powered on at the site, the equipment will spontaneously signal to shake hands with the master station for the first time. The master station will obtain the health status, coordinate position, operating environment and operating parameters of the equipment, so that the operation and maintenance personnel can timely master the operating status of the equipment.