The insulation medium of high-voltage switchgear and its internal high-voltage equipment will deteriorate with the operation time, and its performance will be reduced until the insulation breakdown. In order to avoid electric fire and other serious accidents, partial discharge and temperature online monitoring methods can be used to grasp the insulation status of equipment in real time.

When the high-voltage switchgear and its internal high-voltage equipment (such as PT, CT, busbar, cable connector, etc.) generate partial discharge (partial) due to insulation fault, it is often accompanied by pulse current, electromagnetic wave, ultrasonic, light, ozone, heat and other physical or chemical phenomena and corresponding processes. LY-DM500 adopts ultra-high frequency detection technology. Based on the principle of "field", it receives ultra-high frequency electromagnetic wave radiated during partial discharge through antenna sensor to detect partial discharge. In order to make the test data true and reliable, LY-DM500 adopts comprehensive anti-interference measures such as analog filtering, pulse grouping, periodic pulse elimination, and setting dynamic threshold.

Features

◇ The extraction of the specific frequency band of the discharge signal can effectively suppress the common interference signals in the substation. Then, it can effectively determine whether it is the discharge at the high-voltage equipment or the external interference signal.

◇ Alarm function: alarm status can be given according to the severity of partial discharge.

◇ The partial discharge monitoring subsystem adopts the special statistical method of "abnormal cycles" of our company, which can eliminate the instantaneous pulse impact interference caused by the operation of the interference switch. Generally, the shock electromagnetic wave generated by switching operation only occurs 1-5 times in individual power frequency cycles, and such abnormal cycles are relatively simple. By counting the number of such abnormal cycles, it can be determined whether it is switching operation or partial discharge signal.

◇ All sensors of the partial discharge monitoring subsystem are connected with a single digital bus bar and power supply integrated multi-core cables, with the minimum wiring quantity, greatly reducing the number and complexity of wiring on the switchgear, and minimizing the impact of the monitoring equipment on the original equipment.

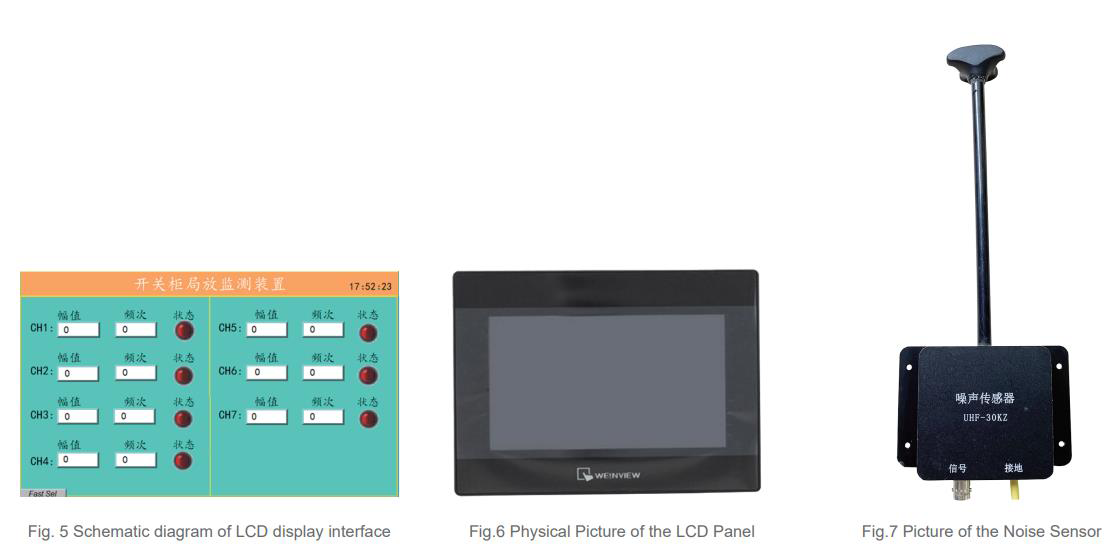

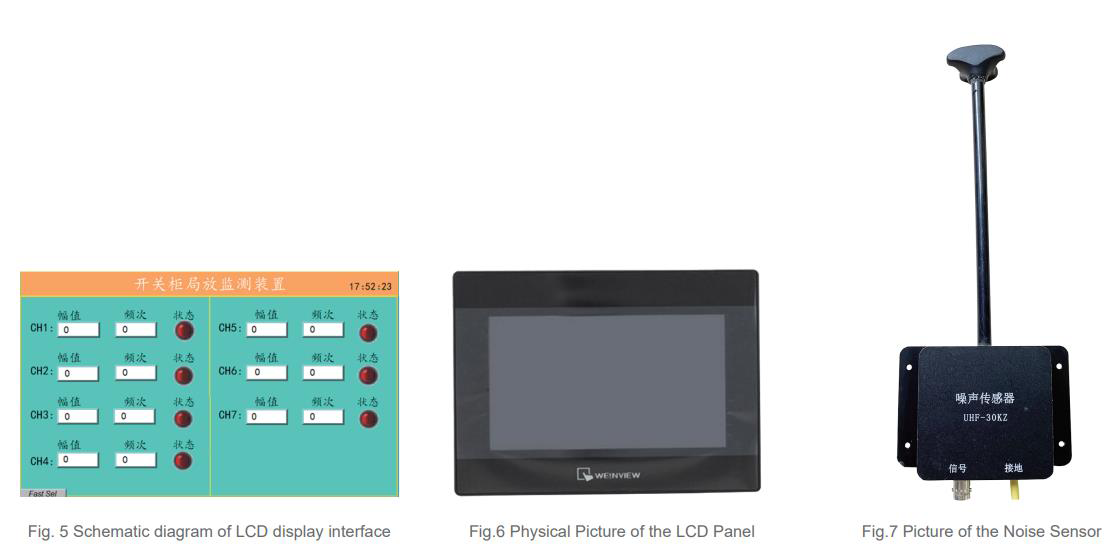

◇ Touch screen displays amplitude, frequency, alarm status and other information in real time.

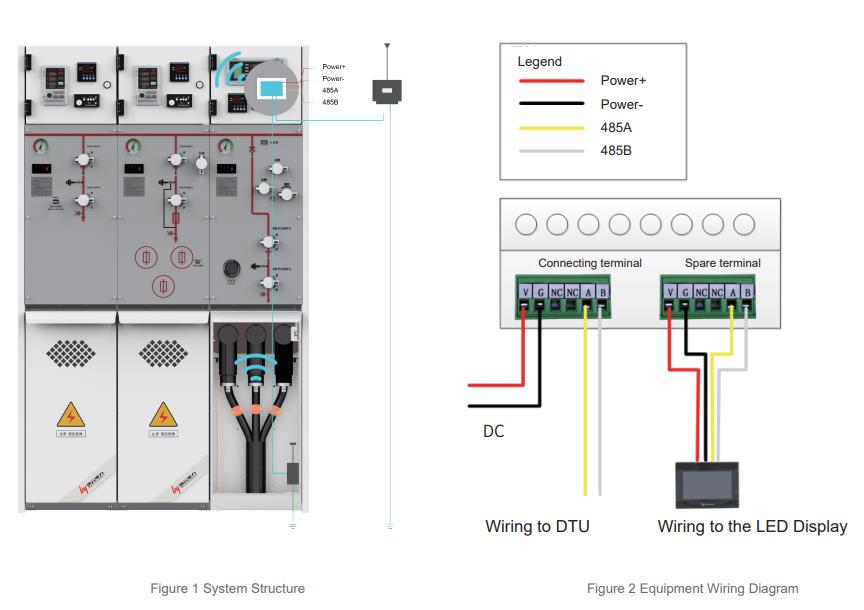

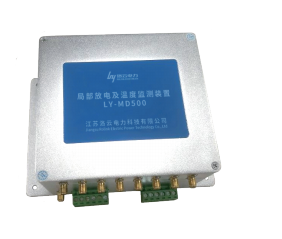

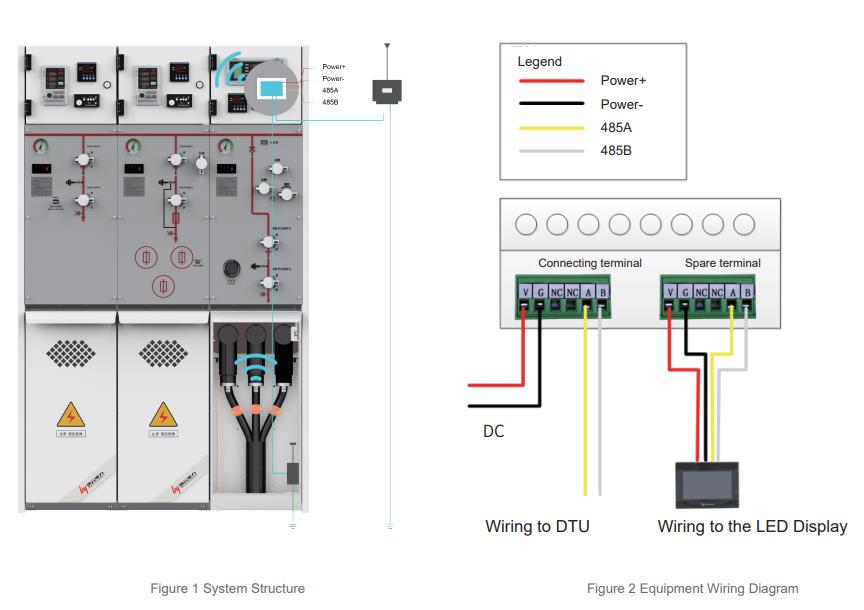

The partial discharge online monitoring system is applicable to the partial discharge online monitoring of 10kV and above voltage level switchgear and its internal high-voltage equipment. It can display the amplitude and frequency of partial discharge at each monitoring point in real time, determine the relative position of the discharge point, give an alarm if necessary, find the insulation defects of the switchgear in time, provide criteria for evaluating its insulation level and aging degree, and provide a basis for the maintenance of the switchgear. Each group of switch cabinets is equipped with a set of partial discharge acquisition host, and each host can monitor up to 7 switch cabinets. According to different users and site requirements, our company has specially developed a variety of partial discharge monitoring technologies and implementation schemes for switch cabinets. Typical device structures are shown in the following figure:

The embedded high-performance processor is adopted to ensure high-speed sampling and greatly reduce the power consumption of the device. Each data acquisition device is networked through 485 bus bar and MODBUS-RTU protocol for remote communication. Each partial discharge collector can be connected serially with multi-core cables integrated with power supply and communication, which greatly simplifies the field wiring.

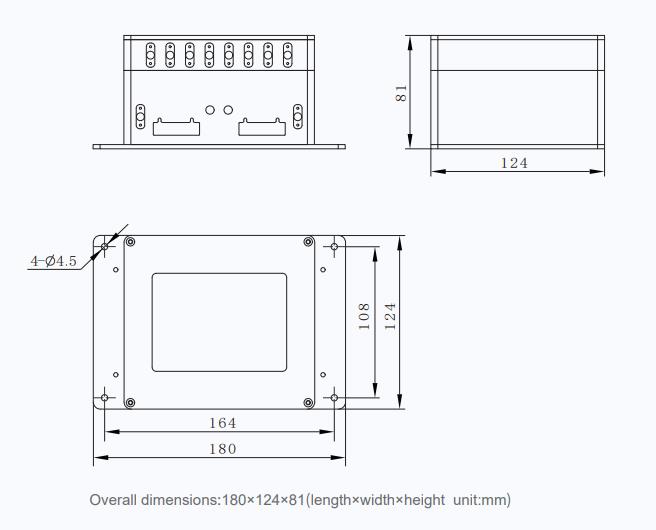

Main technical indicators

| Sensitivity | Measuring range | Operating frequency band | Ambient temperature | Altitude |

| 2pC | 2 - 10000pC | 10M - 800MHz | -40℃ ~ 65℃ | ≤4500m |

| Degree of protection | Fieldbus supply voltage | Housing | Installation position | Power waste |

| IP55 | DC 24V | Aluminum alloy shell | The instrument room of the switch cabinet is fixed on the cabinet wall by magnetic suction | <5W |

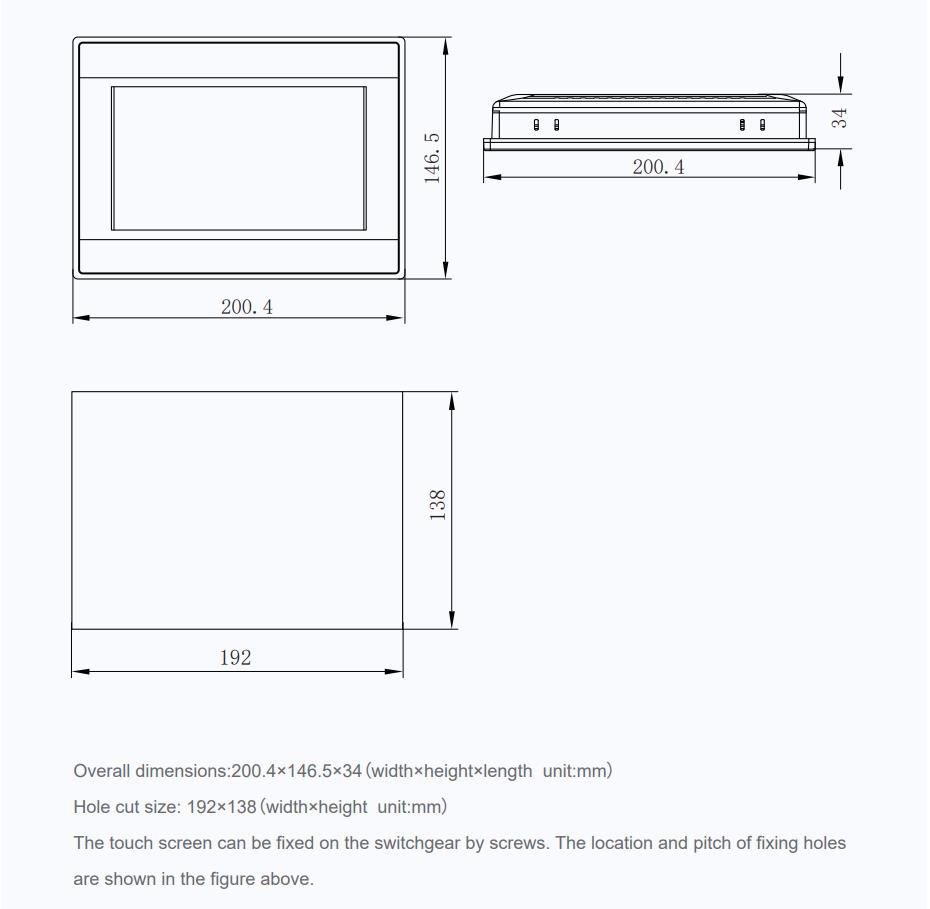

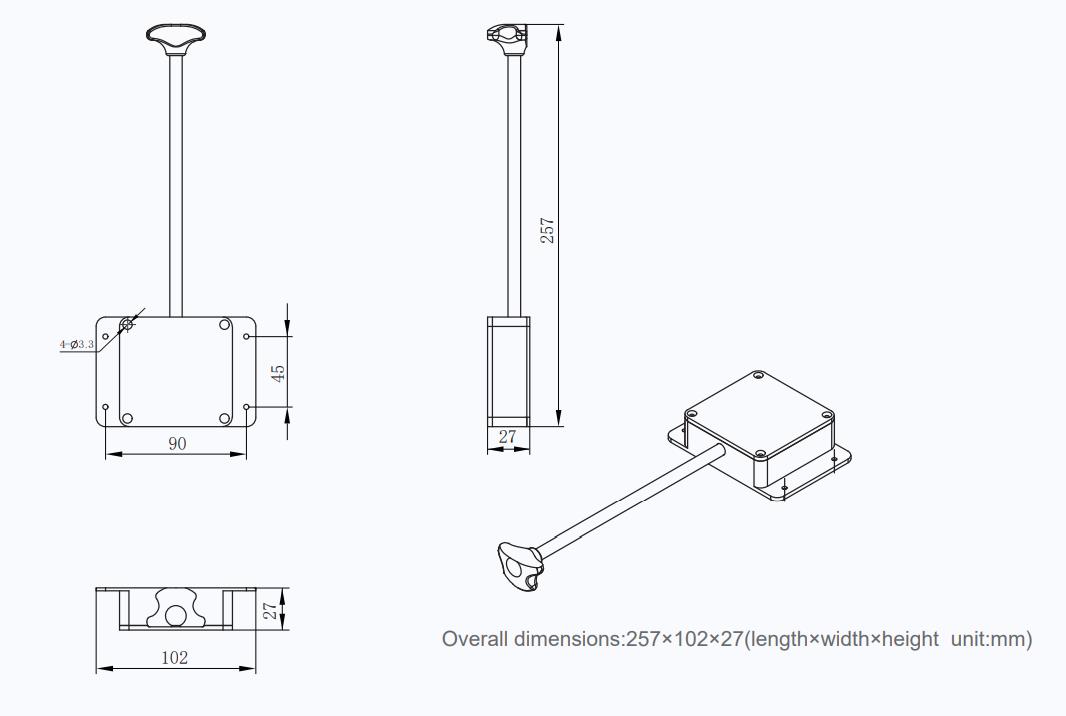

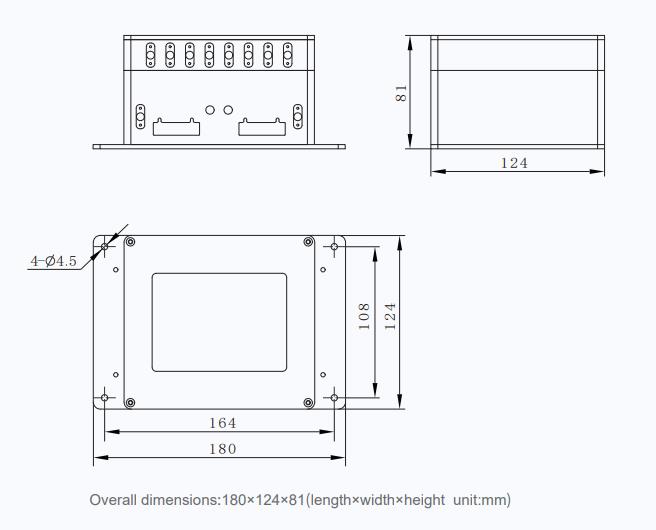

Overall dimensions

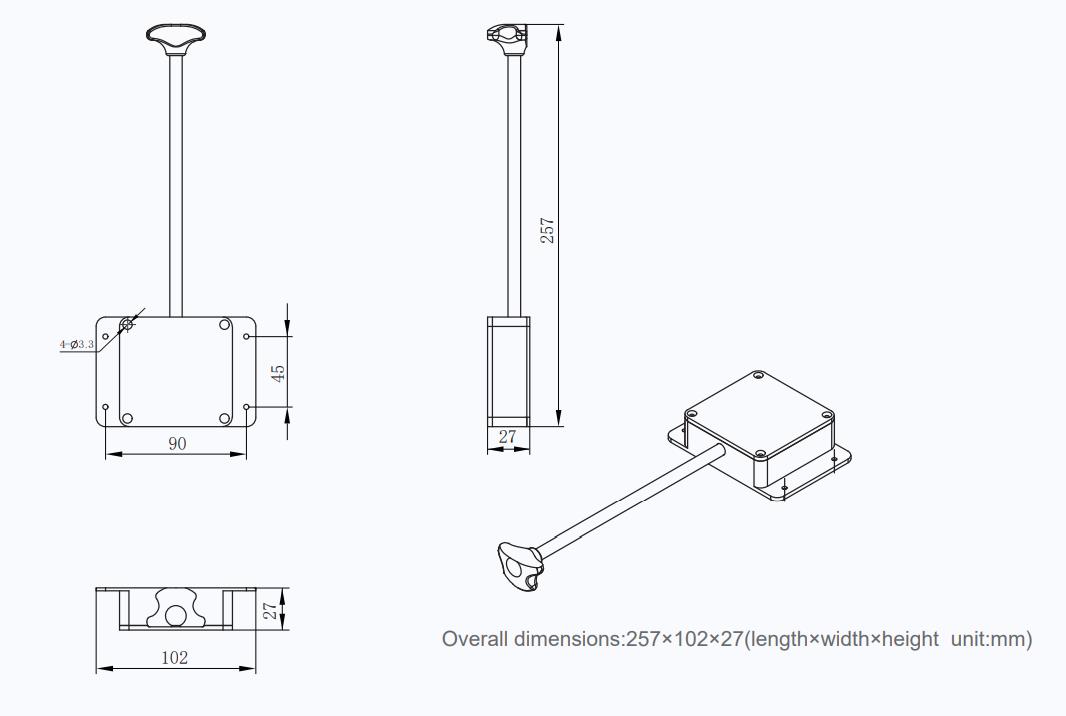

UHF antenna sensor is a partial discharge measuring sensor designed for measuring partial discharge signal, which is easy to install and has high sensitivity. The sensor is applicable to the integrated installation of the switchgear before delivery or the power-off installation of the high-voltage switchgear that has been put into use. The shell is made of aluminum alloy and the surface is treated with oxidation insulation process. It has excellent response performance to the electromagnetic wave signal of partial discharge in the 10-800MHz band of the internal space of the switchgear, and realizes the coupling of the partial discharge signal of the switchgear. The sensor can be directly installed and fixed in the cable chamber of the switchgear or installed on the inner wall of the switchgear with a magnet suction.

Main technical indicators

| Main technical indicators | Operating frequency band | Sensitivity | Measuring range | Response speed |

| 10 - 800M Hz | 2pC | 2pC - 10000pC | 2nS | BNC |

Output interface | Degree of protection | Temperature range | Matching impedance | Housing |

| IP65 | -55℃ ~ 85℃ | 50Ω | Aluminum alloy shell | 270×102×26 |

Overall dimensions

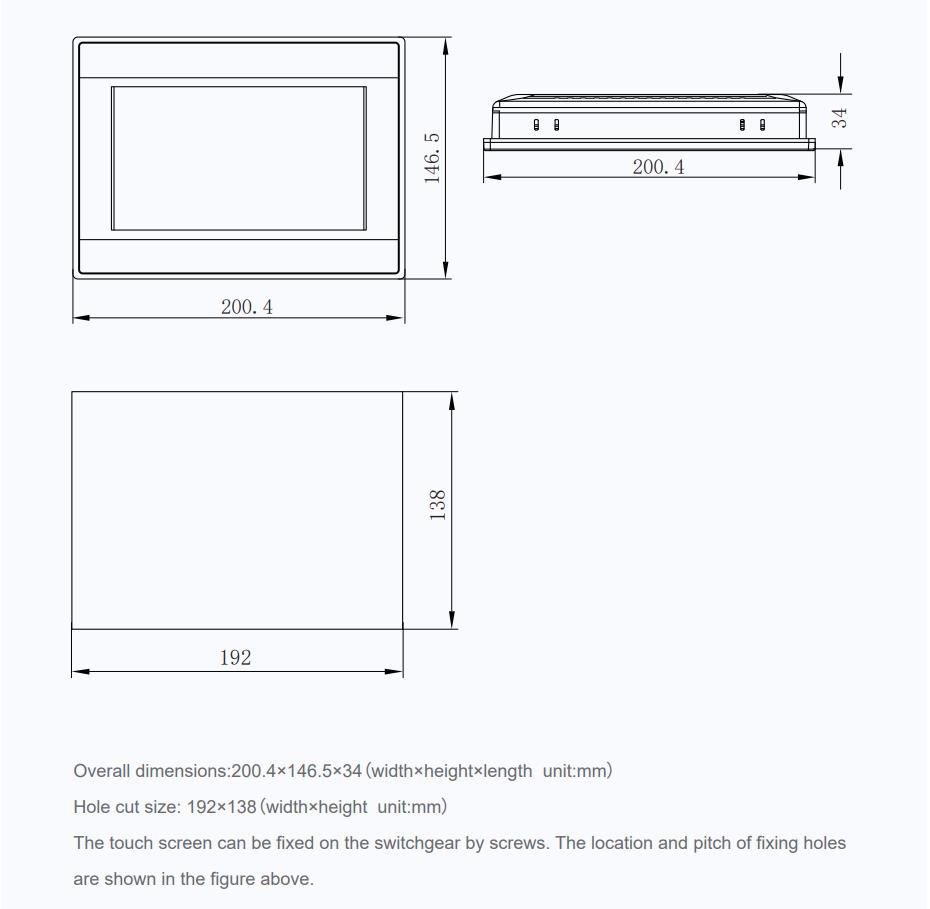

The parameters and dimensions of the noise sensor and the UHF sensor are identical. They are installed at different positions to receive spatial noise interference, and the noise signal and discharge signal are separated by comparison between the signal channel and the noise interference channel. The device adopts touch screen display to display local discharge and temperature status parameters of each monitoring point in real time, including amplitude, frequency, temperature, alarm status, etc. of each channel.

Main technical indicators

| Main technical indicators | Operating frequency band | Sensitivity | Measuring range | Response speed |

| 10 - 800M Hz | 2pC | 2pC - 10000pC | 2nS | BNC |

Output interface | Degree of protection | Temperature range | Matching impedance | Housing |

| IP65 | -55℃ ~ 85℃ | 50Ω | Aluminum alloy shell | 270×102×26

|

Overall dimensions