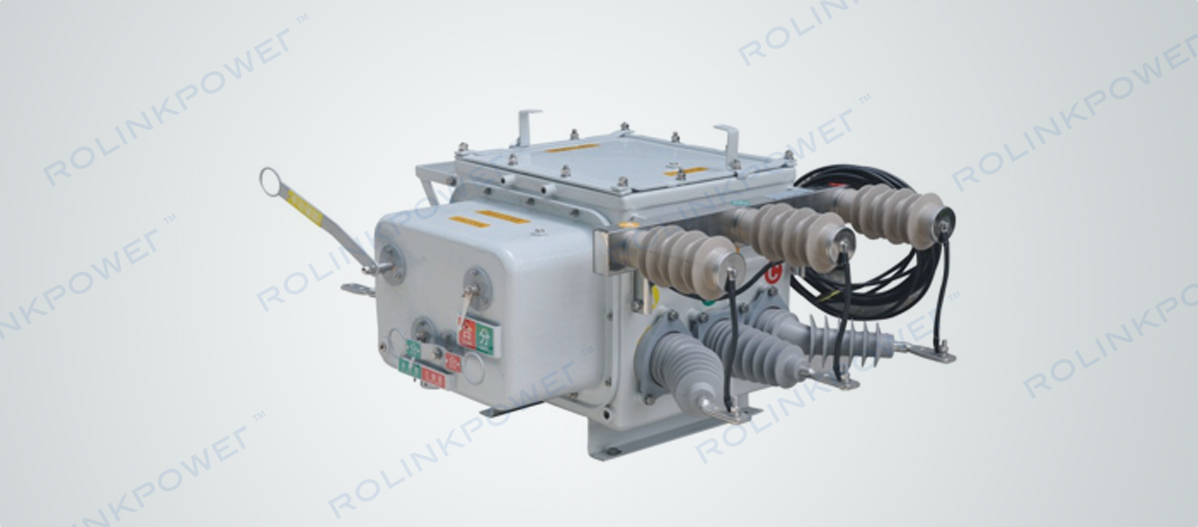

ZW20-12/T630-20 series outdoor high-voltage AC vacuum circuit breakers (hereinafter referred to as circuit breakers) are used for AC overhead power distribution systems with rated voltages of 3.6kV - 12kV, are mainly used as outlets, sections, connections, major branches and users. It is mainly used for breaking and closing the load current, overload current, short circuit current of the power system and switching the grid operation mode. It is suitable for protection and control in substations, power distribution networks and power distribution systems of industrial and mining enterprises, as well as in rural power grids and frequently operated places.

The circuit breaker adopts box sealing structure, which has good sealing effect and can meet IP67 standard. Zero sequence voltage and phase voltage sensors are installed outside the circuit breaker. Low power and high accuracy. The parameters meet the standard of T/CES018-2018 Technical Conditions for 10kV and 20kV AC Sensors in Power Distribution Networks. It is a new generation of high-precision maintenance free products that meet the latest requirements of the State Grid.

The excellent electrical and mechanical properties make this circuit breaker series widely used and favored by users. It is one of the two mainstream products of 12kV outdoor circuit breakers all over the world